|

Performance:

gantry type grooving machine is improved from the conventional table type grooving machine. The V grooving machine has all the advantages of conventional table type grooving machine( such as the sheet is fixed& static. No scratches on its opposite during grooving, simple structure and good rigidity and better stability).

compared with a conventional table type grooving machine, the improvement of the machine as follow:

the rear moving beam is designed to transversal moving, remove the auxiliary clamp and the knife rack can left and right moving.

The driving force transmission system is changed from a straight gear into a skew wheel to increasing the speed, reducing the noise and vibration and ensure the transmission more stability and reliability to prolong the life of gear.

3.The machine is subject to three axis controlling,¡£ Its X axis(longitudinal feed of knife rack) is subject to servo motor control , its axle Y(transversal moving of feeding unit) and Z axis are subject to servo control, it can realize full automatic machining after the parameter are set, comprehensively improving the accuracy of grooving.

4. the worktable can automatically repair after it is worn to prolong life for the machine.

5.The positioning through pressing sheet edges, there is neither contact between the clamping and the sheet surface, no pressing marks on the sheet surface.

6.the grooving machine are treated by tempering to avoid the stresses. Ensure a high accuracy and good rigidity.

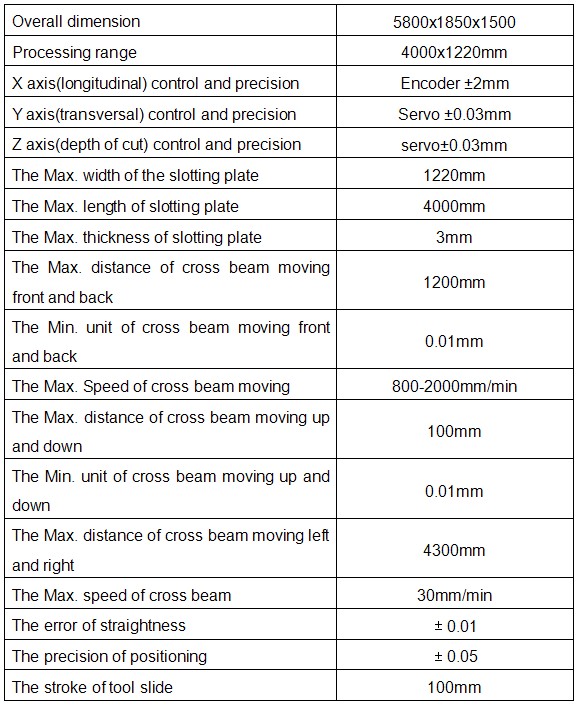

BC- 1220X4000 CNC sheet metal V grooving machine

Technical date:

|