|

Performance:

GBC grooving machine is a kind of latest development equipment, it adopt the steel wire as its transmission system. It instead of the gear, rack and pinion and ball screw, to realize flexible drive. It completely avoid the vibration cased by the rigid connection of rack and pinion. And significantly improve the roughness of groove surface and product quality as well.

the machine have three axis to be controlled, its X axle (longitudinal moving of knife rack), Y axle(transversal moving of rear feeding device) and Z axle(vertical moving of knife rack) are all subject to servo control. It can realize full automatic machining after the parameter is set up, comprehensive improving the accuracy of grooving.

clamping system adopt the hydraulic system to drive, large pressure, reliable fastening force. Lowe noise and small energy consumption.

the rear feeding unit is driven by double screw structure and its surface has high positioning accuracy.

the guild way of knife rack is made of cast iron. it have abrasion resistance and have repair function to prolong the service life

the NC program is reasonably designed and easy to learn to learn. the equipment can realize automatic machining after the parameters are input. there are multiple interlocking safeguard measure for safe operation.

1220X4000

GBC- 1220X5000 CNC sheet metal V grooving machine

1220X6000

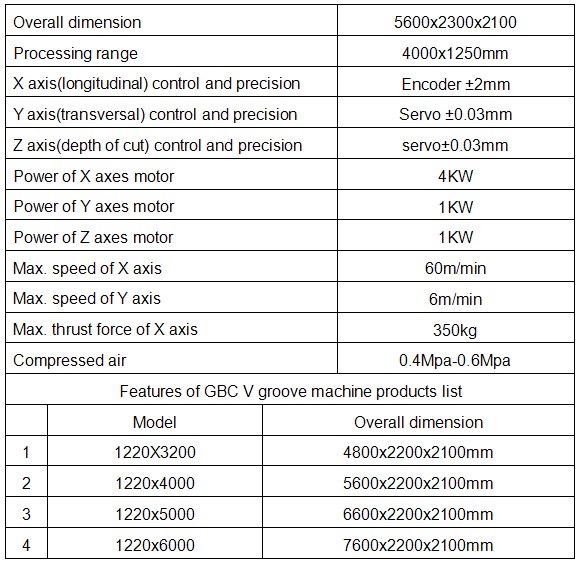

Technical date:

|